"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

01/03/2016 at 18:23 ē Filed to: Spit6

3

3

5

5

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

01/03/2016 at 18:23 ē Filed to: Spit6 |  3 3

|  5 5 |

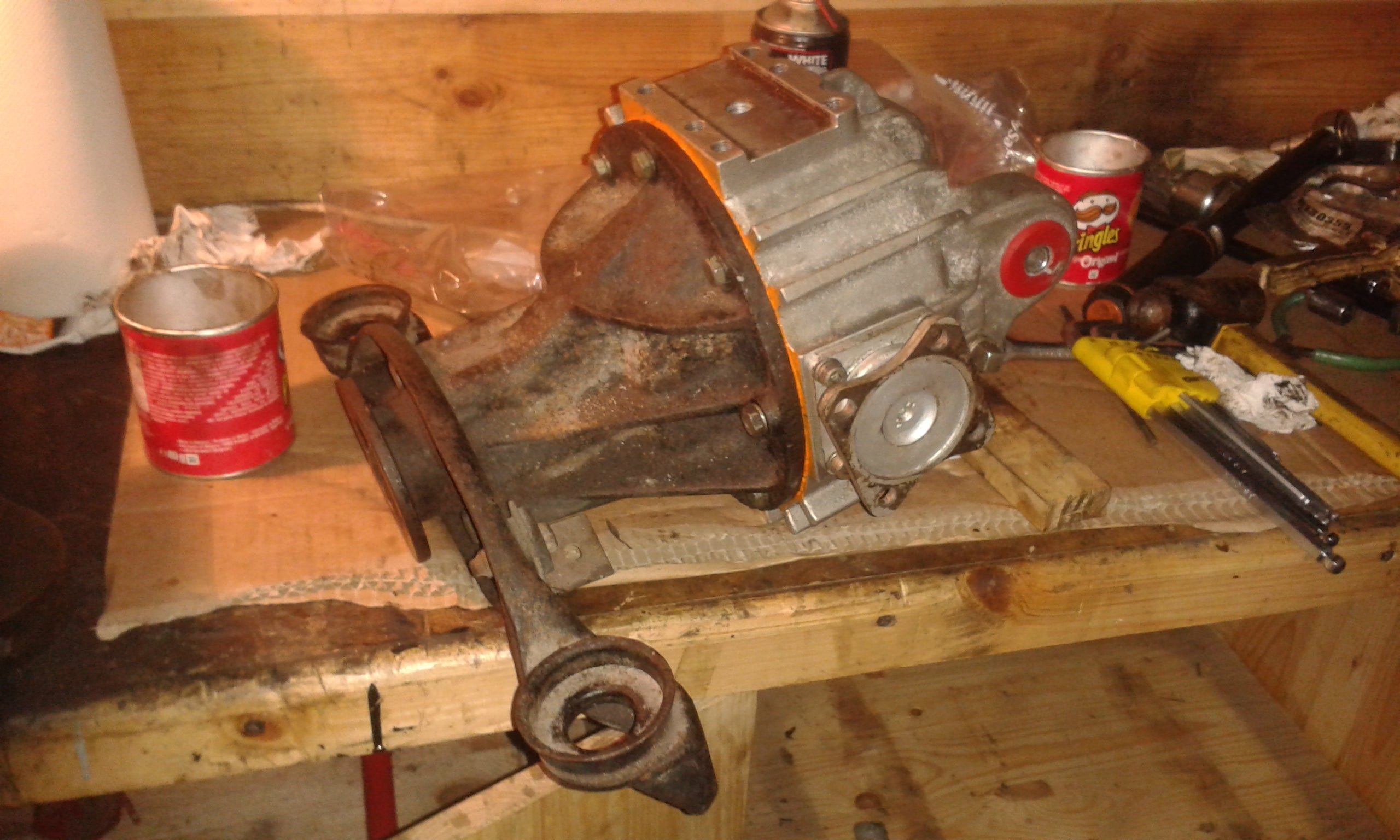

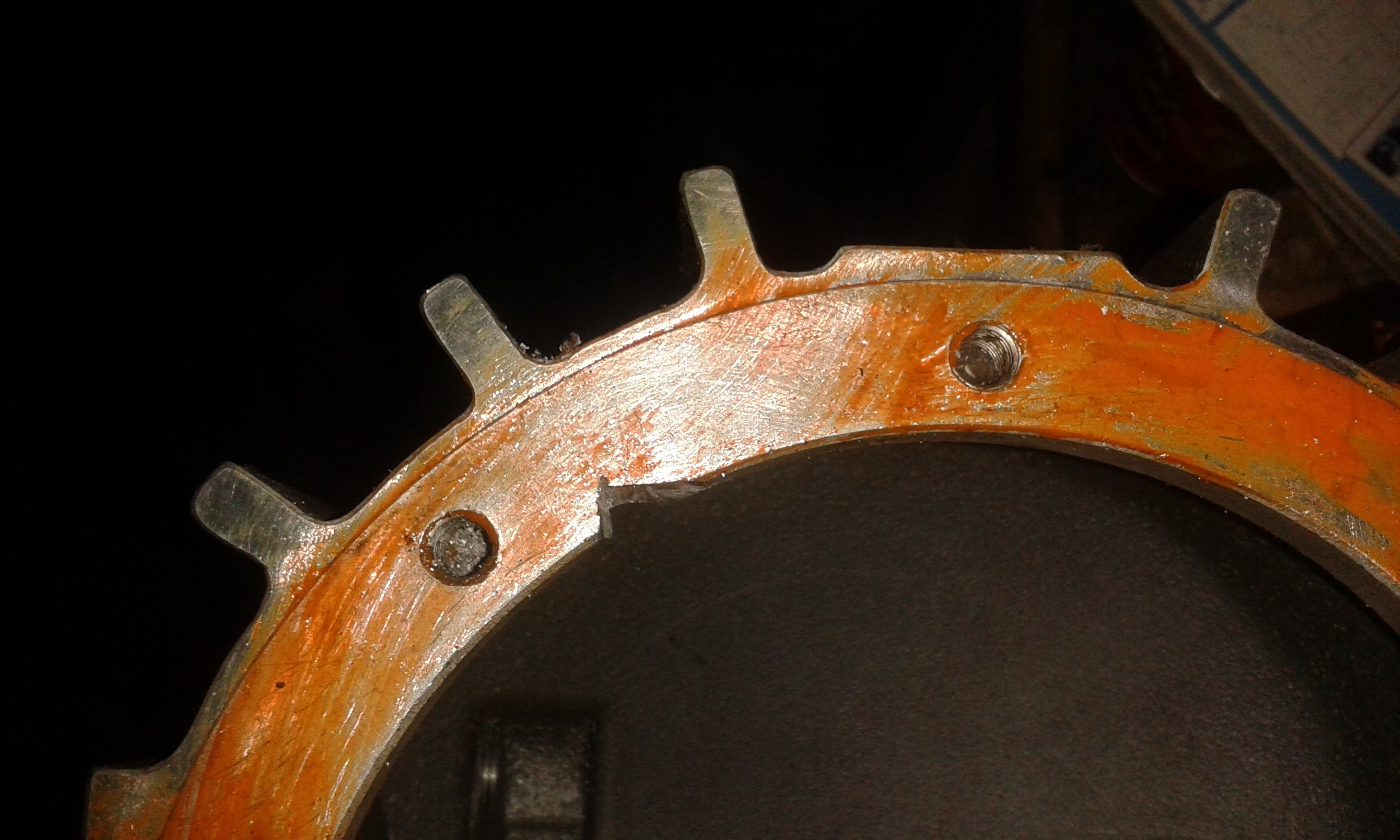

Got the diff back together. Turns out the quaife diff is ever so slightly too big to fit in the alloy case i have (not sure about the standard one) so i had to cut a couple of notches in it quickly before the sealant went off.

Then i started cutting up bits to make my inlet trumpets. Started by making 15mm sections to weld to the trumpets to get the length tuned right to produce harmonic effects at 5750rpm where i should be making peak power.

Turns out its bloody hard to cut a perpendicular cut in a tube without a lathe or jig of some sort. Best i could do was mark it at a dozen points around the outside, link them up with an angle grinder and then file it as close as i could.

Then, halfway through i noticed the tube my 6 quid bellmouths was made from is ever so slightly smaller than the tube iíll be welding it to which just wonít do, so i cut them down a little into the bellmouth a little so as to widen the opening.

Halfway through that so iíll finish cutting then do some practice runs with my tig welder!

gmporschenut also a fan of hondas

> BiTurbo228 - Dr Frankenstein of Spitfires

gmporschenut also a fan of hondas

> BiTurbo228 - Dr Frankenstein of Spitfires

01/03/2016 at 23:29 |

|

http://www.mcmaster.com/#slitting-sawsÖ

could mount a slitting cutter into a milling machine. maybe into a drill press, but I donít know if the part could be moved/secured safely.

BiTurbo228 - Dr Frankenstein of Spitfires

> gmporschenut also a fan of hondas

BiTurbo228 - Dr Frankenstein of Spitfires

> gmporschenut also a fan of hondas

01/04/2016 at 04:41 |

|

If only i had either of those :S

The other issue is securing it as itís thin-wall aluminium tube so clamping it just bends it :S got around that slightpu by sliding a narrower tube inside and clamping both together

gmporschenut also a fan of hondas

> BiTurbo228 - Dr Frankenstein of Spitfires

gmporschenut also a fan of hondas

> BiTurbo228 - Dr Frankenstein of Spitfires

01/04/2016 at 20:40 |

|

I think the only safe way would be a few setup clamps to hold the top lip. not enough (or strong enough) to put an expanding or constricting collet. Thatís a tough job given how thin and weak the metal is.

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

01/12/2016 at 11:41 |

|

Iíve missed these last few updates -very nice. You know, a pipe cutter is just the thing for getting a perpendicular cut, though it doesnít work on a taper for obvious reasons. Canít think youíve done anything with iron pipe lately, but if youíd had a plumber friend...

Meanwhile, Iíve managed to order in a lot of stray parts for the Ranchero. My front upper ball joints, some steering link bits, and a brake conversion kit, amont others. The steering bits get rid of some serious bump steer and convert it to quick ratio (mostly), in addition to getting around the V8 engine better. It looks like Iíll have to mill out the end of my spindles a little bit or source alternate tie rod ends because the V8 ends only sort of go into the I6 spindles, but oh well - the rest of it seems to fit pretty well. Iíve also got a new master cyl for the brakes - two zone, of course, and the conversion kit for front discs and five lugs mostly installed.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

01/13/2016 at 04:50 |

|

Wahey thanks! Just ordered one and itíll make cutting new tube to test different inlet lengths much easier :) I gather that the formulas for getting an ideal inlet tract length are a bit subjective (read: tried 4 formulas, all came out with different answers) so Iíll try and make a few different ones and try them on a rolling road when itís all together.

Very nice :) is it staying unassisted for the steering? Not sure what it was to begin with actually...

You can get dual-circuit master cylinders for Spitfires (standard on the 1500), but theyíre a bit of a point of failure. Thereís a little valve in the middle that I think just operates a warning light, but it breaks relatively readily and you lose braking. Iíll probably go with a single system for mine and a brake bias valve leading to the rears.

Oh, Iíve also had a pretty cool idea for one of my next projects. Iíve thought about taking a GT6 (with a 16v Sprint engine) and welding the body to the chassis to make it a monocoque. Would end up similar to an E-Type with a monocoque at the back and a frame leading forwards to support the front suspension and engine (suitable triangulated against the body to help prevent flex).

Don't think it's been done before so that'll be fun :)